Dissolved Gas Analysis of transformer oil in the United Arab Emirates (UAE) is a critical process for effecting the longevity and reliability of the country’s rapidly extending energy infrastructure. This intricate procedure, bridging the realms of chemistry and electrical engineering, serves as a vigilant guardian against possible defects in basic components of the electric sphere. Dissolved Gas Analysis helps experts understand how transformer oil works and what might cause difficulties.

The Nuances of Classic Dissolved Gas Analysis of Transformer Oil in the UAE

Dissolved Gas Analysis (DGA) of transformer oil in the UAE is a sophisticated procedure that commences with the collection of oil samples. This initial step holds utmost importance, as it forms the basis for correct analysis. The samples are meticulously obtained to prevent any contamination that could skew the results. Once taken, these samples are transported to specialized laboratories equipped with precocious equipment.

In the research lab, the procedure of Dissolved Gas Analysis takes place by gently warming the mineral oil. This gentle heating initiates the liberation of a range of gases that are dispersed within the oil. Each of the gases functions as a diagnostic marker for peculiar types of problems within the transformer.

Diagnosing Transformer Issues through Dissolved Gas Analysis

The second facet of Dissolved Gas Analysis of transformer oil refers to interpreting the results of gas chromatography to find latent transformer problems. This diagnostic process hinges on a deep understanding of the sources and implications of each gas.

Hydrogen: Typically the initial gas to manifest in fault conditions, hydrogen can hint a range of issues, from overheating to arcing.

Carbon Monoxide and Carbon Dioxide: Normally, these gases arise from the degradation of paper insulation. A high ratio of carbon monoxide to carbon dioxide may indicate substantial insulation breakdown.

Methane, Ethylene, and Ethane: These hydrocarbon gases are generated at different temperature levels and can provide insight into the extent of thermal faults.

Oxygen and Nitrogen: Although less revealing, fluctuations in their levels can show marks of oil degradation or external contamination.

Engineers can ascertain the nature and severity of malfunctions in the mechanism by interpreting the proportions of these gases. Case in point, a notable presence of hydrocarbons may imply thermal faults, whereas an increase in hydrogen and carbon monoxide levels could suggest electrical discharges or insulation failures.

Through DGA, it’s not only possible to detect the presence of aberrations but also to track their progression over time. Actions can be taken to rectify complications by utilizing this temporal analysis before they result in disruptions to the operation of the transformer.

The Importance of Hydrogen in Chromatographic Analysis of Transformer Oil

Talking about Dissolved Gas Analysis (DGA) in the UAE, importance of dissolved hydrogen presence in mineral oil cannot be overdrawn. As the smallest and lightest of all gases, hydrogen typically serves as the primary byproduct in response to difficult conditions within power equipment. Detecting hydrogen is, therefore, of utmost importance for early issue detection.

Hydrogen in a transformer is caused due to factors:

Electrical disturbances such as arcing, corona discharge, and partial discharges are primary contributors to hydrogen formation. These disturbances can arise from insulation breakdown, loose connections, or other electrical irregularities within the transformer.

Overheating can have detrimental effects on both the dielectric and paper insulation of electrical devices. This overmuch heat cause the degradation of the components, resulting in the generation of hydrogen and other gases as byproducts. It’s worth mentioning that assorted temperatures of heat can result in formation of unique gas patterns, and hydrogen is one of the earliest indicators of thermal stress that can be identified within the transformer.

Detection and Analysis

Detection of hydrogen in transformer oil is a complex procedure that employs modern testers and methodologies:

- Gas Chromatography: separates hydrogen from other gases dissolved in the oil, enabling precise measurement of its concentration. The chromatograph employs a column that differentiates gases based on their velocity, effectively isolating hydrogen for quantification.

- Solid State Sensors: In some advanced setups, solid-state sensors immersed directly in the transformer oil are employed for continuous hydrogen monitoring. These sensors exhibit high selectivity and can detect even the slightest fluctuations in hydrogen concentration, providing real-time data for proactive maintenance.

Importance of Hydrogen Measurement

Early Fault Detection: The presence of hydrogen, even in trace amounts, can serve as an early warning signal for evolving faults. This early detection is critical for preventing minor issues from evolving into major failures.

Thermal Fault Severity Assessment: By analyzing the rate of hydrogen generation and its concentration comparative to other gases, it makes possible to rate the severity of thermal faults within the transformer.

Challenges in Hydrogen Analysis

- Sensitivity: Detecting hydrogen demands exceptionally precise equipment, as it is often present in low concentrations, particularly in the initial stages of fault development.

- Interference from Other Gases: While hydrogen is a primary indicator, its interpretation must consider the existence of other gases in the dielectric. This necessitates a comprehensive analysis strategy that accounts for the complete gas profile.

Express Hydrogen Content Analysis Using the TOR-2 Device

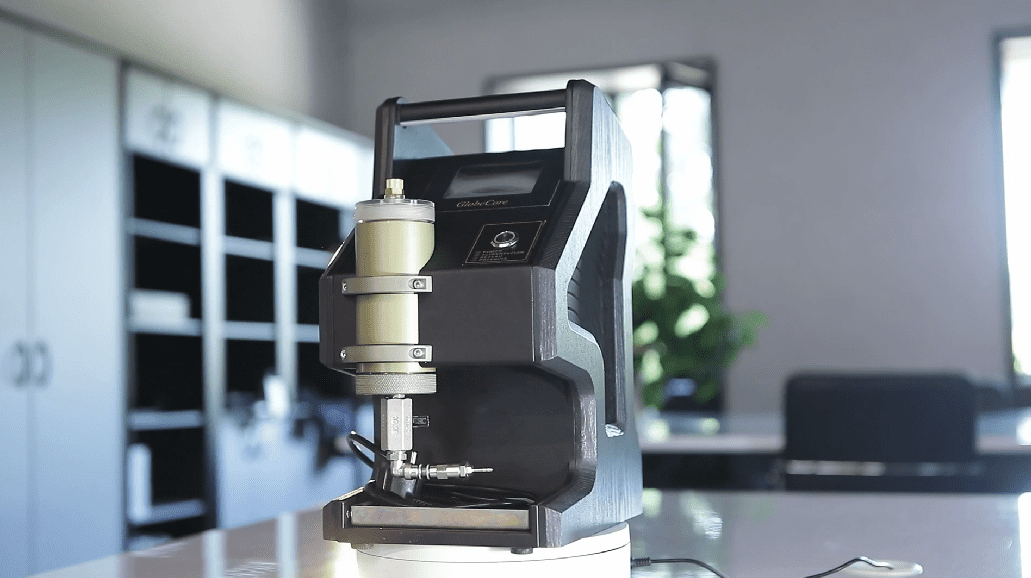

For Dissolved Gas Analysis of transformer oil in the UAE, many clients rely on the TOR-2 transformer oil express-tester, particularly for rapid hydrogen content analysis. This device provides quick and precise understandings about transformer state.

Technical Functionality of TOR-2

The TOR-2 utilizes a highly selective solid-state sensor immersed directly in the mineral oil. This direct approach to measuring hydrogen content distinguishes the TOR-2, ensuring on-the-spot, precise results.

The solid-state sensor employed in the TOR-2 is designed to detect hydrogen at exceptionally low concentrations, for early fault detection. Its precision is pivotal for preventative maintenance, guaranteeing that even the slightest fluctuations in hydrogen levels are identified.

Unlike conventional methods that necessitate sending oil samples to laboratories, the TOR-2 enables on-site, real-time monitoring. This capability facilitates swift decision-making and action, a crucial element in proactive transformer management.

The TOR-2 provides rapid results, which are priceless in time-sensitive scenarios where prompt actions can prevent further transformer damage.

Designed for ease of use, the TOR-2 requires minimal technical expertise to operate.

Advantages of TOR-2 Device for Dissolved Gas Analysis

The TOR-2 device offers benefits that make it an informative tool for Dissolved Gas Analysis of transformer oil in the UAE.

- Moisture and Hydrogen Detection: It can detect both moisture and hydrogen, even in minute amounts, providing a general assessment of transformer condition.

- Compact Size and Portability: Its compact design enables easy portability, facilitating on-site testing in diverse locations and environments.

- Maintenance-Free and Cost-Effective: The device requires no consumables for measurements and minimal maintenance, ensuring a economic solution for long-term transformer maintenance.

- Measurement Reliability: The presence of other gases in the oil does not impact the credibility of TOR-2’s measurements, ensuring valid hydrogen and moisture readings regardless of the oil’s gas composition.

- Simple Calibration: process in the TOR-2 is straightforward, guaranteeing consistent accuracy and trustworthy its readings.

In conclusion, the TOR-2 device for Dissolved Gas Analysis of transformer oil represents a key advancement in mineral oil analysis.

Hydrogen and Moisture ...

Hydrogen and Moisture ...